| Author |

Message |

Bill Davis

New member

Username: Nvbigblue

Post Number: 2

Registered: 12-2001

Posted From: 167.154.26.65

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, April 10, 2007 - 06:17 pm: | |

Hi guys!

I'm finally putting my MAX II back together. I picked up a strong running arctic cat sled with a 440 f/c engine that I've pulled out for use in my MAX. The problem I've run into is that the clutch on the engine is wider than the clutch that was on the original JLO engine. I believe it's a Comet 108exp. At any rate, the problem is that if I line the clutch up with the driven clutch on the tranny, it hits the side of the machine. I'm checking into replacing it with something not quite so wide, but I fear that I'm not going to have any luck. I'm also going to see about possible using the driven clutch off the sled to replace the driven on the t-20 now. If neither of these options pan out, my last, and I do mean last resort might be to 'extend' the body in the spot where the clutch hits it. I know this sounds odd, (and I have to thank my wife for the idea...), but she remarked that the comet clutch is just smaller than one of her cake pans (clutch is 8 1/2' dia.). She suggested that I might pop a hole in the body and then use the pan to gain the extra room needed for the clutch. I looked at it pretty good, and it might work. The pans are really heavy duty (say 1/8' thick) and have a lip of almost 3/4' inch all the way around. If I trim the lip off on one pan and use it as a backing plate, I can sandwich the body between them. I attached a really simple pic of what I mean. The ring would go on the outside of the body, and the complete one would go inside with the 'dish' portion going out. Since I don't really ever plan on spending more than a couple minutes in the water (just crossing a stream or such) and since the metal would mostly be protected behind the tire, my biggest worry is keeping dirt and stuff from coming through the body. Thoughts?

Thanks,

NV

|

Marc Stobinski

Intermediate Member

Username: Jerseybigfoot

Post Number: 54

Registered: 06-2000

Posted From: 68.193.116.132

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, April 10, 2007 - 08:00 pm: | |

You may want to look for a Polaris driven end clutch to fit on the T-20. The belt is about 1 1/2" further inboard of the body than the origional clutch. That way the engine would move away from the body also. You might have to machine a sleeve to match up the clutch to the t-20 shaft. |

Don Kinyon

Member

Username: Oldnatva

Post Number: 44

Registered: 04-2002

Posted From: 67.163.101.210

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, April 10, 2007 - 09:39 pm: | |

Hey, Bill;

The Comet 108 is a great unit and it would be a shame not to use it on the Kawasaki. I don't know exactly what your clearance problem is, but on an Attex I got away with spacing the engine mounts about 3/4" up and forward, keeping the same belt adjustment. Before you install your cake pans, it would be worth a try to heat the area of the body with a heat gun and form a bulge where you want the clutch clearance.

Good Luck.

Don |

Bill Davis

New member

Username: Nvbigblue

Post Number: 3

Registered: 12-2001

Posted From: 206.230.60.75

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, April 11, 2007 - 12:30 am: | |

Hey guys,

Thanks for the input.

Marc, I was thinking that I might be able to use the driven off the sled and see if that would help....

Don, you're a frinkin' genius!! I hadn't thought about making a bulge that way... that's a great idea! My fear was if I went with a different clutch, it might not handle the HP from engine. I've tried moving the engine around for a better fit, and actually if it did go up and forward, it would work better for the exhaust, but the body clearance gets tighter if I go up. But if I heat up the existing bulge and deepen it, it might just work. I flipped the exhaust manifold over and I'm planning on giving it a little v-notch on the top, bending it slightly and then welding it back up. The sled didn't have what I would call a "tuned" pipe, and I'm planning on using the original MAX muffler, but that might change. The engine is not really going to fit under the upper body the same as the JLO, so I'll probably end up cutting the upper body a little for clearance. If the original muffler has a negative effect on the engine, since I'll already have cut the upper body, I can go ahead and use the pipe from the sled. It will be down side up, but I don't think that will matter....

Actually, it's a Suzuki "Spirit" engine. But man, the thing runs great. It's oil injected, and the sled only had about 2800 miles on it. I'm really jazzed about getting this thing running. I'm around 5000 foot here and this engine should give me plenty of power.

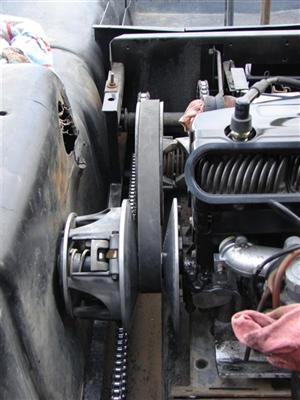

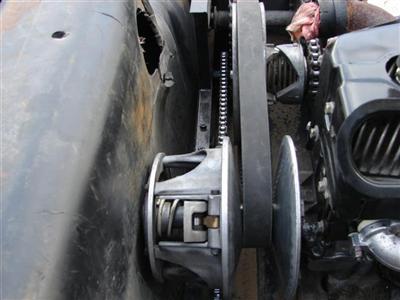

Here's some pics of what I'm talking about for clearance....

Oh, that hole above the clutch was from the a$$hat that had the MAX before me letting the exhaust pipe come off the muffler and melt the body. I've already fixed it by trimming off the "bad" parts with a hot knife, and then using two pieces of steel plate (around 10 gauge I think)and sandwiching the body between them. I put in #10 machine screws about 3 inches apart around the edges and a couple across the center to clamp it. It looks lilke it will work real well. I have added any sealant yet, becasue it may, for some reason, have to come back apart. But once I'm set, I'll seal it up. I'm in the high-desert here, and don't see me using this thing as a boat....

Bill

|

david berger

Senior Member

Username: Davidrrrd

Post Number: 517

Registered: 01-2005

Posted From: 72.72.84.209

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, April 11, 2007 - 11:38 am: | |

Hi bill, thats a great combo with a 440cc in a maxII,

i have an 86 maxII i have beaten to death that had the techumpsa replaced with an arctic cat 440 cc befor i got it.

i hope you resolve your cluch problems.

i think the previous owner had gon the re molding route but mines got a cheep cluch on it thats probly dead.

i added inner bearings to my machine by drilling with long drill bits from outside the machine threw the holes the axel and bearing flangets cover up,

on pasengers side i added 1" squair box tubeing to suport the bearings.

the jackshaft tubes between the sprokets can shear so i added 3 ,1/2" rods by drilling threw the sprokets and welding the rods to connect the smaller sproket set and both the center axel sproket sets, but strenthining the wider jackshaft will be more of a challenge.

you can expect to detonate your chain adgusters as well. but mr clark has a good upgrade to prevent this.

you may also bend your fraim where the rear adgusters are unless you beaf up your fraim there.

mine bent sevearly on both sides in the rear but only a little in the frount.

notice the body bumps out about half an inch for maybe 17" near the adgusters?

picture a 1/4 plate on the outside of your fraim dude.

im trying somthing like that this time, i lernd all this the hard way. ask anyone!

i also have used a techumpsa muffeler for several years, but this time im going to use a jlo muffeler but i welded a larger outlet on it,

for a spark arrestor)

wish i knew where there were some pic's of it i could post right now, but serfice it to say the little cargo area behind you can still make a nifty trunk with a plywood deck atop of it and your going to like a high back seat, just try the idea out.

mines got a little bump in it from the previous owner just bolting the upper down on the engine and payin it no mind.

that whako also put loops made from seat belt in the frount of the floorboard that your feet can get into (and out of when nesesary)

i found i can pull up on my feet to stay down on the seat or push forward agenst the straps to hold my back firmly into the back seat cushon as nesesary to stay in the driveing position under the crazy bumpy semi out of control conditions found at speeds over the 35 mph most others can travel at, you can hit 50 on a long straitaway but you cannot use your brakes beyond say 25 - 30

mph if you wish to live verry long.

insted you will lern to use only your nutral on the latterals and throttleing one side or the other to correct your heading at those higher speeds.

~enjoy~ |

Mike Cummings

Intermediate Member

Username: Hydromike

Post Number: 57

Registered: 03-2005

Posted From: 141.149.254.227

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, April 12, 2007 - 10:08 am: | |

he-he... You couldn't be more correct about the lack of steering above 30, Dave. Steering with a T-20 at 40 or so changes from active to passive rather quickly. In my Superchief and older ST racer, I leave a lot of slack in the band engagement, so each decision to turn is a very concious one. If (when) I become airborne and the arms are bouncing all over the inside of the machine, I don't really run the risk of engageing or disengaging either side of the trans. It really becomes an art.

After looking over your pictures, you're in good shape. Take Dave's and Isaac's advise. SLOW heating (don't use a propane torch) and GENTLE pressure is the key. I like the idea of using a scissor jack on it's side with a casserole dish. It's a real GRADUAL process. As Isaac states, be ready to cool down in a hurry to "lock in" the ideal shape should you reach it. You can estimate how much you need to "bump out" with the clutch on there.

I don't think 50mph is out of the question with that machine if your gearing is set up for it. The T-20 can handle 50 without even blinking. The tires can handle 50, the axles can handle 50 w/o any big bumps, the whole driveline can handle 50. The limiting reagent in this whole deal is the safety of the machine after you get it going. A helmet, roll cage (not just a bar) and harness is a good idea. |

|