| Author |

Message |

Ray Kohls

Member

Username: Bw6

Post Number: 20

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, March 01, 2007 - 05:46 pm: |

|

Hi All, I'm taking Howards advice and starting a new thread. I promise to be honest and objective about the results. When problems appear as they will please post your comments/solutions. First I would like to say that my purpose in building the Bushwacker was not to try and build a better Argo or Max. I respect the abilities and history of both of those manufacturers. I wanted to see what I could design starting from a blank sheet of paper. I have incorporated many of your ideas from the "Dream Machine" postings. The result is the "Bushwacker AATV" |

Howard Hoover

Intermediate Member

Username: Howard_hoover

Post Number: 60

Registered: 10-2005

Posted From: 4.161.111.150

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, March 02, 2007 - 08:26 am: |

|

Ray, I hope you didn't think I was trying to tell you what to do But it's a little easier trying to read about one topic in one post instead of two topics in one post. It's no big deal I've done it my self but I just figured you would have so much interest that you would want ot to have your own thread. I really like your drive system design. It's less complicated than my Gates Belt design for my AATV & looks a lot easier to set up. Although I still might use belts depending on the weight & cost variables I am using a VW eng. & Full Auto trans with a locker in the tranny custom built one of a kind locker for it.

1. So I was wondering what kind of HP the units you are using would take?

2. And any idea what the loss of power is through them ?

3. What supplier are you using for them? and cost?

I like the way you enclosed the engine and transmission area! Is that to keep water out of that area to keep from flooding the engine etc.? I like the light you put in the body that will be great if it gets dark on you and you need to fix something.

I can't see any of your drive system in the pictures are you not showing it purposely? to keep some of it secret? I did look at the schematics it's pretty straight forward & easy to read though.

How much space do you have between your tires & the body? I'm sure it's probably enough but it doesn't look like much? Great Job Ray |

Ray Kohls

Member

Username: Bw6

Post Number: 21

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, March 02, 2007 - 12:06 pm: |

|

Hi Howard, I didn't take any offense, I am new to posting and having your own thread makes sense. I didn't know that you are designing your own, GREAT! What size VW engine? I always liked the VW stuff. I have a VW Passat TDI, but have had Bettles, Vans and Westfalia's. The last Vanagon I had I did an engine swap from the 2.1 waterboxer to a 1.8 Jetta/Golf it was coupled to an automatic, it was a great performer.

Howard the Tuff Torq is rated at 360 ft/lbs of torque.

http://www.tufftorq.com/prods2.asp?PID=17

and peak load of 1930 ft/lbs, that is a huge number. I think it could handle the VW torque output easily. Also with the built-in locker, wet brakes, and 66 lbs it seems like a winner. But my verdict is out until I finishing my testing. I am registered as an OEM with them through another company.

The hood area is sealed, I designed it and the rear for a 45 deg. entry/exit from the water. With the front hinged hood another benefit is unrestricted access for inspesction/maintenance. The schematic shows a simple way to eliminate chains, but poly chain would work as well. I have a friend that manages a transmission products company who can get me some great pricing on stuff, but I still found the poly-chain to be expensive. Howard I laughed about "keeping it secret", some of my ideas are patentable, however I choose to share them with the forum, so I'm really not trying to keep them a secret. Ask and you shall receive

I have about an inch between my tires/body, I can adjust this outward if needed. My thinking was the farther out you go the more bending stress on the axles and the wider the machine width. To plan for tracks later on I put on longer tire studs to space out as needed when and if the need arises. They are also the replacable type and not welded in so they can be replaced if every damaged.

Howard, if you dont mind I want to keep my costs out of the postings because it can lead to "self-promoting" as per the rules. If you want to know costs then please email me, thanks.

Howard, I'm interested in your project, could you give me a little more info? Thanks for your interest. |

Howard Hoover

Intermediate Member

Username: Howard_hoover

Post Number: 62

Registered: 10-2005

Posted From: 4.161.23.235

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, March 03, 2007 - 07:27 am: |

|

Ray, I haven't had much interest in my project probably because of the VW engine. So I will save everyone else the boredom and just email you about it. Chris Davison in California is also building a VW based 8x8 with a 4 spd. I talked with him about it for a few years. I have also been talking to Peter Hartley in New Zealand for a few years now he is building 6x6's & 8x8's with water cooled subaru engines & going for a Military contract he has lots of patents & innovative ideas he can remove the entire engine & trans in about 10 minutes I guess it has quick disconnects all over it?? I have lots of his pictures too but I can't send them on or post them anywhere as he has asked me not to but I can give you either one of their emails if you would like although I haven't heard from Chris in a while. I'm sure Peter Hartley would share some ideas and photos with you if your ask him.

That place where you got your transmission in Morristown Tennessee is very familiar I used to date a girl there and lived not too far from there in Bean Station TN.

I forgot to ask you about your 90 degree reducers are you getting them from the same place? and what are they rated at as far as HP input? Thanks Howard |

Ray Kohls

Member

Username: Bw6

Post Number: 23

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, March 03, 2007 - 08:42 am: |

|

Hi Howard, yes I would like to learn more about your project, please email me. And I wouldn't mind corresponding with Peter/Chris. I haven't sourced out the 90 deg. reducers as yet. I know a few companies make them. Maybe on my next project, I will design a shaft drive 6x6 or maybe Rob will beat me to it. I hope he beats his health issues. or maybe Rob will beat me to it. I hope he beats his health issues.

I have an open question for everyone, regarding swimming tire design, why some work and others don't? I can appreciate the chevron thing and lug height, but some tires just don't swim at all! This always puzzled me, because I can show you a picture of my "float-an-atv-days" and those big lug ATV tires worked fine on an ATV, but put them on a 6x6 and they go no-where. If you check out the AV-4 vids they use different tires I think they use the "Bear Claws" now and it just scoots along. My guess it is something about the middle tires interrupting the efficiency of the other 4.Float ATV} |

Howard Hoover

Intermediate Member

Username: Howard_hoover

Post Number: 65

Registered: 10-2005

Posted From: 4.161.107.172

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, March 04, 2007 - 02:39 am: |

|

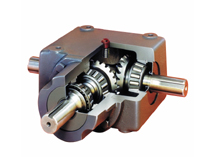

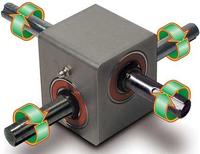

Ray, Is this similar to the units you are using? |

Ray Kohls

Member

Username: Bw6

Post Number: 24

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, March 04, 2007 - 01:35 pm: |

|

Hi Howard, that type will work, but the type I'm thinking about are "hollow-shaft" meaning there are no external shafts, you decide which is the input/output shafts and slide them right through the reducer. |

Howard Hoover

Intermediate Member

Username: Howard_hoover

Post Number: 66

Registered: 10-2005

Posted From: 4.161.106.166

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, March 05, 2007 - 07:58 am: |

|

Do you have to use a splined shaft in it or does it have a squeeze lock of some kind on it? |

Ray Kohls

Member

Username: Bw6

Post Number: 26

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, March 05, 2007 - 02:12 pm: |

|

No, they have a continuous key/keyway, with a set-screw locking collar each end |

christopher j Davison

Junior Member

Username: Chris_davison

Post Number: 12

Registered: 06-2006

Posted From: 66.81.40.246

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, March 06, 2007 - 01:33 am: |

|

Im kinda partial to the hollow shaft gearboxs with keyless hubs |

Howard Hoover

Intermediate Member

Username: Howard_hoover

Post Number: 67

Registered: 10-2005

Posted From: 4.161.19.74

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, March 06, 2007 - 06:57 am: |

|

Ray, are you using aluminum or steel drive shafts? |

Howard Hoover

Intermediate Member

Username: Howard_hoover

Post Number: 68

Registered: 10-2005

Posted From: 4.161.19.74

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, March 06, 2007 - 07:00 am: |

|

Hey chris I haven't heard from you in a while.

How is your project coming? |

Ray Kohls

Member

Username: Bw6

Post Number: 27

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, March 06, 2007 - 08:59 am: |

|

Hi Chris, Howard told me you are building an VW powered 8x8 how is it coming along? Could you email me or post some pics?

Howard, I'm not a fan of aluminum shafts. All my shafts are 4140 steel. Heavy but strong. |

christopher j Davison

Junior Member

Username: Chris_davison

Post Number: 13

Registered: 06-2006

Posted From: 66.81.45.169

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, March 06, 2007 - 11:05 pm: |

|

Hey Howard whats up?

Havent done a lot to my machine but did buy some brkts from a 4x4 shop made to weld to a roll bar to mount lights or antenna. I bought some rear tail lights also from wallmart and an electric brake controller for my newly purchased GMC truck. My machines trailer has elect brakes.

You should see how good it looks now painted black. This white and silver truck looks good parked next to my silver vette. Then my mom is too old to drive anymore so she gave me her Honda Accord silver also just like my Nissan.

I got to sell a car or two ins is killing me.

Done any more on your mach?

Chris |

christopher j Davison

Junior Member

Username: Chris_davison

Post Number: 14

Registered: 06-2006

Posted From: 66.81.45.169

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, March 06, 2007 - 11:20 pm: |

|

Hi Ray havent talked to you yet but welcome to the post. Let me go thru my pics and em you some

Chris |

Rob Sandera

Intermediate Member

Username: Rob_sandera

Post Number: 69

Registered: 03-2005

Posted From: 4.91.128.194

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, March 07, 2007 - 01:20 am: |

|

Thanks Howard yes I’m in the fight of my life. A maniac did this to me holding me against my will without medical care till ulcers were all through me. They finally turned cancerous. I was also forced to take large overdoses liver destroying drugs when I had a genetic liver disease, Doctors also believe they damaged my brain as they permanently altered hormones. They tried to wipe me off the face of the earth by phony reports by people who have never even seen me. Had I been diagnosed with the high calcium in my blood 12 years ago this wouldn’t have happened. There were some medical reports showing it. It caused all the gastro illnesses. There were 600 million dollars in lawsuits filed. I may need to get to the University of Chicago Hospital and am broke from spending 1000s on gas. There is no cure for stomach cancer other then to cut it out early. Many people die of a heart attack form the surgery. I been wanting to post but busy with medical records and surgeons. Ray there is a few flaws in your design. One is weight the other now you still really didn’t change ground clearance. And you need electric clutches like mowers not centrifugal, yes you have to use 90 degree bevel gears no worm gears. I’ll explain later. And no I’m not building a shaft drive I think I came up with something better. If I ever get through this I’ll build all you guys the six wheeler of the future. The design has been on the books for almost 2 years I constantly strive for any improvement and all your ideas to cover all the bases. Roger all I can say is its got to be a riot being in that class at Carnegie Mellon. They need to raise more money making some crazy movies with that thing. I can just envision it being operated by Gladiators. |

Rob Sandera

Intermediate Member

Username: Rob_sandera

Post Number: 70

Registered: 03-2005

Posted From: 4.91.128.194

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, March 07, 2007 - 01:22 am: |

|

oops posted on the wrong page guess I'm tired sorry |

Howard Hoover

Intermediate Member

Username: Howard_hoover

Post Number: 69

Registered: 10-2005

Posted From: 4.161.16.104

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, March 07, 2007 - 03:50 pm: |

|

Chris, I finally got my engine & trans together My back has been so screwed up Ihaven't felt like doing a whole lot plus I have been working 6 & sometime 7 days a week but I will try and get some mounts made here shortly and I will send you some pics. I don't have a regular digital camera but I have a game cam will work almost as good. |

christopher j Davison

Junior Member

Username: Chris_davison

Post Number: 15

Registered: 06-2006

Posted From: 66.81.46.37

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, March 08, 2007 - 01:00 am: |

|

Howard Ill em you a pic of my truck its got a 6 in lift and 35 in tires. I know how work goes i just finished a 12hr shift. Still looking for an engine.

chris |

Howard Hoover

Intermediate Member

Username: Howard_hoover

Post Number: 70

Registered: 10-2005

Posted From: 4.161.107.31

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, March 12, 2007 - 04:27 pm: |

|

Hey Ray, can you post more pictures of your machine on this thread? |

Ray Kohls

Member

Username: Bw6

Post Number: 28

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, March 12, 2007 - 11:37 pm: |

|

Hi Howard, Ok here are a few that people may find interesting. One is from the early part of the project, all the bent parts are coming together. The others are my method of doing a authenic military camo pattern. This is a four part WW11 US Summer Verdant pattern. First import your file into a graphics program ie: Photoshop, Photopaint etc. Then size the pattern to your object, like AATV, rifle, trailer etc. Then print out the pattern onto a overhead slide material (coated side down) (grayscale). Cut out with an "exacto knife" use this as your template. Go to craft supply place and buy can of "light tack" spray. Spray coated side so template will adhere to object. Then apply paint using small roller and stiff large artist type brush. Repeat next color and so on until top coat. For exact color matching print out camo on a good quality photo grade paper, take to paint shop for computer matching. Have fun creating an authenic camo pattern.   |

Howard Hoover

Intermediate Member

Username: Howard_hoover

Post Number: 71

Registered: 10-2005

Posted From: 4.161.20.177

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, March 14, 2007 - 06:30 am: |

|

I'm ready to see that thing in action. Have you test drove it yet? |

Ray Kohls

Member

Username: Bw6

Post Number: 31

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, March 14, 2007 - 08:48 am: |

|

Ok, here is an update. I have started the testing. The first thing I noticed was the transmission mounts were too weak, I made them out of aluminum to save weight, and they started to buckle under load. I redesigned the mount out of steel, much stronger, but a little heavier. The next thing was the final ratio's. I picked 1.8:1 which would give me a top speed of 35 mph. It was fine for small turns and straight line but no good for doing doughnuts. So I changed the ratio to 1.27:1 and immediately noticed an improvement. This will lower the top speed to 23 mph. I am going to do some more testing today. Will take some pics and post. |

Ray Kohls

Member

Username: Bw6

Post Number: 32

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, March 14, 2007 - 05:16 pm: |

|

Broke her in today! Enjoyed 30 min ride, was cautious, checking for chain stretch, noise, play etc. but everything was OK. The engine is running too rich, need to figure out how to adjust those jets. This skid steer transmission would benefit from me lowering the final ratio some more. Most of these transmission run at 1:1. This will lower my top speed again, but make it easier to turn, and easier on the whole drive train. The suspension seat was beautiful, run over some ruts at full speed that would have launched the rider of any other type of AATV. All in all not a bad day!    |

Marc Stobinski

Intermediate Member

Username: Jerseybigfoot

Post Number: 53

Registered: 06-2000

Posted From: 68.193.116.132

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, March 14, 2007 - 09:29 pm: |

|

Ray; Great looking machine. Is your decision on the gear ratio selection based upon the braking capacity or engine loading. Its surprising to find a large spread in gear ratios in older rigs. 14:1 in my Scrambler. 7.3:1 in my ATTEX, and 11:1 in my Hustler. |

Ray Kohls

Member

Username: Bw6

Post Number: 33

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, March 14, 2007 - 11:20 pm: |

|

Hi Mark, great question. It is very interesting to find such a large spread as you say. My decision is mainly based on braking capacity. The Tuff Torq KT-35 transmission requires a force of 171 lbs to reach its maximum braking limit. Via the mechanical advantage of long control levers in 2 locations I can reach the working limits with much less than 171 lbs force. However once I lockup the one side, the torque required to rotate the machine is quite considerable. The engine, transmission, torque converter, chains, axles etc can handle the task, but I feel that the final sprocket ratio is still too high. Its like trying to take off in 5th gear on a 10 speed bike. You probably can do it, but its quite a strain. The ratios are as follows: Torque Converter 4:1, Transmission 15:1, Final Sprocket Ratio 1.27:1 The easiest way to lessen the strain is by reducing the final to 1:1. This will give about 20 mph @ 3600 rpm. Then the easiest way to increase speed is up the engine rpm to the 4,000 range. Also big lugged tires may go through the mud well but are a brute to skid steer. Will do some fine tuning tomorrow. |

Ray Kohls

Member

Username: Bw6

Post Number: 37

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, March 29, 2007 - 07:10 pm: |

|

Well the ice is finally off the pond, so I got to Baptise the Bushwacker today. I was a little cautious, wondering if I forgot a weld or pinhole, but she floated beautifully. The tires performed as expected, poorly. Tried forward and reverse hardly swam at all. So on to plan B, which is the dual prop setup. I plan to keep the mudlites because they are excellent on terra-firma, but quite aggressive when turning. Here are a few pics.     |

philip w.cox

Advanced Member

Username: Philipatmaxfour

Post Number: 307

Registered: 01-2005

Posted From: 199.246.2.9

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, March 30, 2007 - 07:41 pm: |

|

Wow Ray, Floats high in the water, looks good. I am very interested in your twin prop idea. I assume you have seen the twin electrics on the Fred Sains Argo add on the classifieds section of this site? Twin props powered by the machine's motor sounds too good to be true. If you get it to work you may get a lot of offers. I am many hours East of you on the 401 but I would love to see your machine in the water wearing my tires! Maybe if we both go to Ohio.... Good luck W.Philip Cox |

Ray Kohls

Member

Username: Bw6

Post Number: 38

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, March 31, 2007 - 09:48 am: |

|

Hi Philip, I was pleased with the buoyancy it did sit pretty high, which gives me the option of more payload or higher speed. Right now I would like speed. I did look at the twin electrics, but didn't like how vulnerable they were to damage if you backed up into something. If I were do use electrics I would retract them differently so they wouldn't be so exposed to damage. Philip I have 4 options for a water drive, which way would you go?

1. Dual Trolling Motor setup, I have the 50 amp charging system, but would need to carry one or two deep cycle batteries (weight). To control they would be tied to micro-switches on the levers, pull left lever, left trolling motor stops, right powers you into a left turn etc. Could forward one motor reverse other for a very tight turn.

2. I have designed a fold-up paddle wheel that fits inside of your rim, that extends via the centrifugal force of the tire. When stowed nothing extends out past the face of the rim. Could mount in all rims or as many as you want.

3. Dual prop setup that is driven from the rims of your tires. Uses a 9" prop x 7" pitch. You can install and remove in 10 seconds. Disadvantage is it sticks out about 12" from tire sidewall. I would mount on rear wheels only. You can install and remove while floating.

4. Dual prop setup that is driven from rear axles, via a hollow-shaft 90 deg. reducers. Props exit between tires at rear. The props could be controlled via 12v clutch, centrifugal clutch or simple removed when not needed (5 seconds each) This setup is more involved but would probably give you the best performance. But would cost the most.

So what do you think? What kind of tires do you have Philip? I am planning to go to Ohio and a few others never been to one, looking forward to it. |

philip w.cox

Advanced Member

Username: Philipatmaxfour

Post Number: 309

Registered: 01-2005

Posted From: 199.246.2.9

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, March 31, 2007 - 01:18 pm: |

|

hi Ray, here are two pictures of my friends, one in a Bigfoot and one in an Avenger towing trailers in the water. We go in the water a great deal. I read on this board that there are many owners who almost never go in the water. Any of your 4 options seem like a dream, too good to be true. I have the optional factory 26 inch tires on my MaxIV. They provide a better water speed than most people expect. But for distances further than you can travel in ten or fifteen minutes another means of propulsion becomes something that you really need.

I think option 4 would require that at least part of the prop be lower than the bottom of the machine. As long as that is possible it would be the ultimate to me.

Option 3 nearly as good. Option 2, I am pessimistic. But then we both know that you are smarter than I am! I don't think Option 2 will work. Please, please, please prove me wrong. Option 1 we have tried big electric trolling motors and dual electric towing motors but have not found any that fit the task. None of us has yet tried the air cooled 5 hp Briggs and Stratton motor. They only weigh 56 pounds. I would like to try one or maybe two of them but easier to mount on Argo's than on my MaxIV.

Look forward to meeting you Ray. W. Philip Cox.  |

Ray Kohls

Member

Username: Bw6

Post Number: 39

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, March 31, 2007 - 03:31 pm: |

|

Philip, thanks for the excellent post. I loved the pics. I only got into this 6x6 venue because of the water opportunities, so water performance is very important to me. Thanks for the feedback regarding the electric motors, I wondered about the thrust, you saved me some $$$. I have already purchased everything for option 4, but was willing to try other options like #3. The whole prop is below the bottom of the machine in both #3 and #4, they rotate up, before you go on land to prevent any damage. Philip I think I will try #3, it requires the least amount of mods to my machine and is easily adaptable to "ANY AATV". My original goal was 10 mph, but because of hull speed limitations I don't think I can achieve it. I should have some pics to post in a few weeks.

As far a being smarter, that remains to be seen, sometimes a Max or Argo looked pretty good to me. I had a chance to drive an Avenger with half-tracks this past week up in Sudbury, very nice. The only things I wish it had was a suspension seat like mine, a bit narrower and lighter. Because the swamps were still partly frozen we had to break ice to get through. An Argo Ice Breaker, now there is a concept! Philip do you have 4 or 5 bolt rims on your Max IV? |

christopher j Davison

Junior Member

Username: Chris_davison

Post Number: 17

Registered: 06-2006

Posted From: 66.81.44.45

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, March 31, 2007 - 04:20 pm: |

|

Hey guys how about a personal watercraft pump

no prop in the water and nothing hanging below the hull. run it off the motor or elect motor or closed circ hydraulics. Ive already purchased a used one for $ 200.00 from a seadoo 650. |

Ray Kohls

Member

Username: Bw6

Post Number: 40

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, March 31, 2007 - 05:34 pm: |

|

Hi Chris, I like the idea of a jetdrive but after personally riding the PWC I found it to be very suscepticle to floating debris, it would get sucked into the intake grate and plug it up. It liked nice clean, deep water. Also if you picked up any suspended sand it would sandblast it. The pump runs very close tolerances for efficiency. It also likes a lot of horsepower and rpm. The smallest jet I know of is the Merc 25/20 used on Jon boats. The Seadoo 650 Rotax develops about 60 hp. also I believe the PTO drive runs at very high rpm, two things I lack in my AATV. I dont believe you will have any problems running it off of your Subie or VW but its not a good fit for me. I know the props aren't perfect and they also get fouled, but are matched to my 23 hp. vanguard. Thanks for you suggestion Chris. |

Howard Hoover

Intermediate Member

Username: Howard_hoover

Post Number: 77

Registered: 10-2005

Posted From: 4.161.17.166

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, April 01, 2007 - 01:53 am: |

|

Well I am very sorry to hear that your tires don't perform in water as I have ITP Mudlite's also although I think my tread pattern is slightly different than yours I have the 28 in diameter tire & I believe the tread is spaced a little farther apart between lugs, it probably won't make much difference though. |

Ray Kohls

Member

Username: Bw6

Post Number: 41

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, April 01, 2007 - 08:38 am: |

|

Hi Howard, those tires on the pic you sent me look a little different than mine. Like you said the treads are spaced apart farther, but the pattern looks the same. I think yours may perform better. I also found that the slower you go the better they perform, but basically they are useless in water. I will be doing some more water testing, to see if improvements can be made. They may not be good in water, but I can tell you they are superior on land. I was hung up in a water filled creek with very steep banks and the machine climbed vertical in reverse trying to get out! If your machine has a enough power to spin the tires and keep the lugs clean, you can go through just about anything. |

philip w.cox

Advanced Member

Username: Philipatmaxfour

Post Number: 312

Registered: 01-2005

Posted From: 199.246.2.9

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, April 01, 2007 - 04:03 pm: |

|

Ray, My MAX IV tires are mounted on 12" rims- 5 bolt stud pattern. I have a spare pair mounted on garden tractor rims that I use as duallies when I want to be silly. Glad to hear that you liked the Avenger--if you think that seat is hard, wait till you try a seat in any other machine. W.Philip |

christopher j Davison

Junior Member

Username: Chris_davison

Post Number: 18

Registered: 06-2006

Posted From: 66.81.43.27

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, April 02, 2007 - 11:29 pm: |

|

Ray I see your problem with the limited hp and rpm you must have a prop with all its inherent problems a prop also needs a rudder too. The prop

is dangerous and just hangs down banging into everthing. You need to come up with a way to fold or slide it out of the way when not in use.

I chose the pump for all its inherently good

reasons like putting along in 16 inches of water

where the tires dont touch and being able to swim around the machine in safety no rudder and the ability to reverse. Im not looking for 40mph

12mph would be great on the water and ive always planned to put a 1/2 inch stainless screen over the grate biggest prob is plastic bags in the water. Ground clearance was a consideration also nothing below the hull

Chris |

Ray Kohls

Member

Username: Bw6

Post Number: 42

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, April 03, 2007 - 08:45 am: |

|

Hi Chris, yes a pump would be nice, but a prop will have to do. I don't feel I need a rudder with a dual prop setup, the props will be on each side of the machine so they should allow a turn by only engaging one at a time. I also have designed a retraction system to allow for shallow water and land use. My design speed (without slip) is 13.25 mph, but its not going to happen. I would be happy with half that. I should be able to report some results in a few weeks. If it performs well, it could be installed in any AATV. Those split T-20's will allow it to do donuts in the water. |

christopher j Davison

Member

Username: Chris_davison

Post Number: 20

Registered: 06-2006

Posted From: 66.81.40.227

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, April 14, 2007 - 10:55 pm: |

|

hey Ray can you draw a pic and email it to me I would like to see what youve designed Ive designed or modified many things at work. Im a maintenance chief engineer at work. |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 56

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, April 15, 2007 - 10:03 pm: |

|

Chris, if you don't mind I'm going to keep this design off the records. I'm going through the patent process, so I am not able to disclose any details at this time. |

TH3

Member

Username: Th3

Post Number: 41

Registered: 01-2005

Posted From: 4.253.31.84

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, April 27, 2007 - 09:20 pm: |

|

we have cypress knees in the water, some you cant see until your tires climb up on them and almost dump over the 6x6. very scary if you are loaded in 10 foot of water. driving props with tires rotating would not be good for me here where i ride. the electric trolling motor is what i use, it allows me to bump off of under water obstacles instead of climbing up on them upsetting the stability of the 6x6.

here are a few ideas i ran through my head....

dual trolling motor heads mounted on a rear jack plate that would lift up in the clear for crossing dry ditches and lower for water travel would be nice. a sliding plate that had pin holes in c channel on each side of the plate would let you slide the plate up as high as the channel is long, even up to the top of the engine compartment if the channel was long enough. the only problem would be the motors mounted so close together would make it harder for the twin motors to turn the 6x6.

i use a clamp on 35#(i think, i painted over the label three years ago) thrust mincota 4 forward and 2 reverse speeds mounted up front on a mount welded to the winch bumper. the mincota is kind to the battery, low 12v draw. i have yet to feel the deep cycle battery draw down on an outing.

i estimate the two trolling motors would push the 6x6 faster than the tires with no problem. the maxIV will get about 4 mph in the water with just tires . i feel like two mincotas will do 5 or 6 mph on high speed.

with two mincotas i could separate the control heads and motors from the shafts and mount the heads up front and the motors out back on jack plate or even dual swivel brackets that would rotate down to position the motors behind each wheel for protection from impact and increased turning speed/response(the farther apart the motors the quicker they will turn the 6x6). with the heads mounted up front you dont have to make a controller. a twist handle in each hand with 4 forward and 2 reverse speeds, you should have all the steering control you could want. all you would have to make would be the mounts for the heads and motors and extent the wires from the head to the motor.

more in post two.... |

TH3

Member

Username: Th3

Post Number: 42

Registered: 01-2005

Posted From: 4.253.31.84

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, April 27, 2007 - 09:33 pm: |

|

post two.....

the head mounts could be a piece of pipe the same dia. as the original shaft welded to the front bumper, bent to place the heads right where you wanted them. just slip the head on the pipe and tighten down, simple and easy.

the motor mounts could be just about any way you wanted to mount them. i would make a dual swivel. each swivel would consist of pipe with the same dia. as original shaft welded together similar to a swing arm like what is used on the front of a 4 wheeler or the letter A with a few more cross bars in-between. the top of the A would mount the motor and the bottom of the A would be the swivel point where the arm would connect to the mounting shaft in a way that would allow the arm to swivel on the shaft(just weld a piece of pipe across the bottom of the A to slip the mounting shaft in).

the mounting shaft would be welded to the hitch plate holding the trailer ball(some reinforcement of the hitch plate area and the mounting shafts would be in order after the arm were installed to prevent flexing under load-piece of cake) with a mounting shaft on each side of the hitch plate this would allow each motor to be independently swiveled down behind each rear tire. when swiveled up, the motors would be almost touching together.

swivel arms held inplace by holes drilled through mounting shaft in up and down position for pins. motor wires run inside the pipe then through the body some place waterproof.

if you could imagine your arms as the swivel arms with your fist as the motor on each end and your shoulder as the swivel point at the rear hitch. arms up over head w/ biceps toughing head=motors in dry land position, arms down just alittle lower than shoulder height=motors down ready for water.

the mounting shaft could be angled down slightly to allow the arms to raise away from rear bumper for clearance when in stowed position if needed but i think the angles required on the arms to clear the rear tires will also allow clearance on the rear bumper. hard to tell without my max at home to look at.

just some ideas ..... |

TH3

Member

Username: Th3

Post Number: 43

Registered: 01-2005

Posted From: 4.253.38.34

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, April 28, 2007 - 12:01 pm: |

|

you could even mount some electric actuators to

each arm to raise and lower the arms with a

switch or two.

increasing water speed has been a dream for most

of us that spend time on the water. its not an

easy task to come up with a method that will

not cause a problem on dry land because it

hangs down too low catch on a log or dig into a

dirt bank when trying to back out of a creek

bed or hangs out unprotected to get damaged

from impact. i am excited that you are building

a working solution to that problem. its all

about having your cake and eating it to. best

of luck on your project. i cant wait to see it. |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 60

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, May 02, 2007 - 05:18 pm: |

|

Thanks TH3, for the great (thought out) ideas. I like thinkers, that provide some details to their suggestions. I completely understand your idea. I purposely picked the new 50 amp. version of the Vanguard 23 for that reason to run dual trolling motors. But was wondering about how they would perform. I contacted the "Do ya Dare Floaters" for their specs/performance numbers which were 4-7 mph for their 70 lbs thrusters. But didn't like how vunerable they were to backup damage. However a lot of other posts re: trolling motors said that they didn't really perform that well. Many wanted a solution that utilized their existing engine for propulsion. I have been persuing that avenue. But like any approach there are pros and cons.

TH3, I like the idea of the "A" mount and getting the props behind the tires for protection. Also separating the heads is another good idea, along with the actuator to lift/lower. If I went to the dual trolling motors I would tie the two motors together using a common tie rod arrangement (like on any car steering). But instead of connecting it to a steering wheel I would use my power window steering mechanism. Then I would mount the dual trolling motors to a common bracket that would be attached to an electic actuator to raise/lower. I would also install a circular prop shroud to protect the prop blades. Steering would be via micro switches mounted on my steering levers. So to steer left I would pull back on my left stick, this would activate the 12v steering motor to rotate the props clockwise, thereby swinging the stern in a c.c.wise direction thus turning me left. (Right turn is just the opposite). To go straight after the left turn pull back on the right stick, the props will rotate c.c.wise, when the AATV is going straight keep both sticks forward, turing stops props are straight. I would not lock the dual trolling motors so that if I hit a submerged obstacle they would simply flip up like any outboard motor. If I knew it was getting shallow I would activate the 12v actuator and lift up the dual trolling motors out of harms way. To stow I would lift them all the way up and pivot them horizontal and secure along the rear deck of the AATV. |

TH3

Member

Username: Th3

Post Number: 44

Registered: 01-2005

Posted From: 4.253.36.231

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, May 02, 2007 - 11:20 pm: |

|

you bet ray,

say..... if you use micro switches to control the motors will you be able to control the speed of the prop or will it just be a motor-on/ motor-off switch?

i was thinking how nice it would be to be able to speed up or slow down the motor in forward or reverse. it seems like it would be easier to steer if you had more control over the speed of the blades and you would also have the ability to conserve battery power if needed by selecting a slower speed.

when im duck hunting in flooded timber i sometimes need to slip around with the trolling motor on low to keep things quiet, bumping into a tree at 3 or 4 mph can make quiet a racket if im trying to slip around stealth like.

maybe you could use multi micro switches, the farther you push the stick the more switches trip speeding up the motor? i dont have a clue how they are wired so im not even sure this is would be feasible.... |

Frazer RM Ross

Junior Member

Username: Beeman

Post Number: 16

Registered: 04-2005

Posted From: 69.31.235.234

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, May 03, 2007 - 01:24 am: |

|

TH3,

The best way to control speed is to use PWM (you can buy a control module to do this), which breaks up a constant feed of DC power into pulses of power (duty cycle... time on compared to time off). By controlling the duty cycle, with a fixed frequency you can basically have 0-100% motor speed control.

I think you could by a module that could do 80 amps or so for $80CAN.. or build your own for cheaper. |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 62

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, May 03, 2007 - 08:41 am: |

|

TH3, I was thinking about using my "Maximizer" http://www.minnkotamotors.com/support/faq.asp?pg=general&pt=8

for speed control. On my Minn-Kota the Maximizer is separate with curly cord connections, it would be mounted on the dash for (fine) speed control. For course speed control I can easily reach the telescopic handles and select speeds 1-4,R. I believe that the newer trolling motors have this feature built in to them, so it may take a little work to separate them or purchase/build a new one as Frazer suggested.

I never thought about the hunting angle, but appreciate the need for speed control. In hindsight the trolling motors would be better for stealth conditions, than an AATV driven solution. Hmmmm..... |

TH3

Member

Username: Th3

Post Number: 45

Registered: 01-2005

Posted From: 4.131.72.44

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, May 03, 2007 - 09:42 pm: |

|

more stuff to chew on........

one of the problems with an electric motor is

lack of power. it seems the key to making an

electric motor work at its best would be placement

of the motor in relation to the body of the 6x6.

i noticed that when i used my trolling motor up front

it didnt pull the 6x6 very well going forward

if i didnt have the motor/blade extended all the way

down where it would clear the body. the more

clearance the motor had from the body, the

more thrust it would have. im guessing that

the same is true for the back of the 6x6 to a

certain extent. i believe that if the rear

mounted motors had the ability to be lowered

below the body or tires that they may push

the 6x6 faster maybe even another mile an hour.

of course one would only lower

the motors that low if he/she knew that there

would not be any underwater obstruction to

impact the motors, for example say a river

crossing or any open deep body of water.

with the motors mounted on an electric actuator

the depth of the motors could be changed

with the flick of a switch, easy to do while under way.

you would have three positions for the motors:

1-stowed for dry land,

2-shallow running to protect the motors behind

the body/tires in obstruction filled water,

3-deep for maximum speed in deep obstruction free water.

how would you know the position on the motors?

i dont know.....yet. |

christopher j Davison

Member

Username: Chris_davison

Post Number: 22

Registered: 06-2006

Posted From: 66.81.40.151

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, May 04, 2007 - 12:37 am: |

|

Hey guys Ive been reading the posts and thinking

and have an Idea think about a 1.5 inch stainless

square tube 4 feet long. At the top a motor elect or hyd. whatever hp. you think you need mounted perpendicular to the tube with a 1 inch wide timming belt pully on it. The belt goes down to a 3/4 in shaft mounted parallell to the motor with bearings and a prop. Put a rack and pinion gear to crank it up and down and attach it to your trailer hitch so it can pivot right and left. This setup can give you all you need

steering height adjustment and the ability to unplug it from the trailer hitch when not needed

also you can change ratios for different prop sizes. |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 63

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, May 05, 2007 - 11:50 am: |

|

TH3, you're right about the prop depth, for max. speed the prop must have no obstructions front or rear. I just did a quick drawing to see how I would mount the trolling motors on my Bushwacker. It looks like I would need a 36" shaft length to get me below the hull at the stern. The most practical way to mount them would be using my 2" hitch receiver. But instead of raising and lowering I think a pivot arrangement would be simplier. I would just utilize the existing Minn-Kota pivoting mounting bracket, just unlocking it. Then a 5" single actuator would give me a shallow, deep and everything in-between position. For stowing I would go to the shallow position, de-couple the actuator (pin), loosen the mounting screws, pull the trolling motors up to the horizontal stow and secure. I would position the motors inside the tires, because this give the shortest position to clear water in front of the prop. To assist in turning I found by leaning side to side with the power on the machine turns very sharply, so I think that the close spacing of the props should not be a factor. The only thing I haven't figured out is how to allow the motors to kick up if they hit an under water object as they are connected to the actuator. Electric actuators are not very forgiving, however an air cylinder is via air compression or spring relief valve. Attached is a pic to illustrate.

Chris, I also like the simple idea of how to power a prop using the tube and timing belts. An inexpensive motor is a treadmill type, their on ebay for around $75.00. Their speed would need to be reduced as well as the voltage but should work fine.

If anyone needs hi-res, just email me.

|

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 64

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, May 05, 2007 - 11:53 am: |

|

Sorry wrong file, here is the right one. |

christopher j Davison

Member

Username: Chris_davison

Post Number: 23

Registered: 06-2006

Posted From: 66.81.43.183

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, May 05, 2007 - 02:13 pm: |

|

thats the beauty of my Idea change ratios for what ever you want in rpm to match your hp and prop size. Or start with a 30/1 inline gearbox

and do the same. all these parts are avail. at Graingers or Mc-Master. Want more resolution on your speed control pull out the speed pot. and put in a ten turn pot of the same wattage. There is even a digital 3 button pot. If you can get a small hyd pump on your rigs motor you can utilize

your full eng hp via a hyd motor. |

TH3

Member

Username: Th3

Post Number: 47

Registered: 01-2005

Posted From: 4.131.78.47

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, May 05, 2007 - 07:11 pm: |

|

christopher,

i too like your idea. its easy to put together

and install/remove. i would have to use a 12v motor

because i dont have hydraulics or the payload

capacity to install a hydraulic system.

how would you control the steering?

i sit in the front of my 6x6 (maxIV) and wouldnt

have access to the rear to operate a tiller handle.

i was just wondering if you had thought about how it

might be done. i cant think of an easy way to do right at the moment........

it may be easier to run a dual fixed set up and control

things with the motor speed/prop direction for

turns.

wow, i just thought about something.........when the belt

on my 4 wheeler gets wet it slips.......

i wonder if this belt would slip?....

i guess with enough pressure it might grip

but that may put the motor in a bind, robbing power.....hmmmmm.....

maybe use a drimmel tool to

grind grooves in the pulley surface to let the belt grip under the water?....... |

TH3

Member

Username: Th3

Post Number: 48

Registered: 01-2005

Posted From: 4.131.78.42

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, May 06, 2007 - 12:26 am: |

|

i remember reading something about an air cooled

outboard a while back but couldnt remember who

posted it so i did a search online and found a

couple of air cooled 4-cycle outboards priced at $750.

the first was a honda 2hp that weighed 27lbs, had a

1/4 gal fuel tank, 360 degree steering, and only

had forward w/an automatic

clutch. the other was a 5hp briggs that weighed

56lbs with a 3gal remote tank, didnt have 360 degree

steering but had forward-neu-reverse gears.

twin honda outboards?......hmmm.....

total weight only 60lbs?......hmmm......

360 degree steering?....hmmmm......

if i only had $1500 to

play with.

ive never water skied behind a 6x6 before..... |

Frazer RM Ross

Junior Member

Username: Beeman

Post Number: 17

Registered: 04-2005

Posted From: 69.31.235.234

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, May 06, 2007 - 11:31 am: |

|

"ive never water skied behind a 6x6 before....."

Now THAT would be a site to see.. and a new sport. Water/Land skiing all at the same time. |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 65

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, May 06, 2007 - 06:00 pm: |

|

Hi Guys, well now that the warm weather is here I noticed that the Vanguard 23 and the KT35 was getting a bit warm. When that happens on the Bushwacker, the engine runs rich and doesn't run very smooth. And on the KT35 tranny with the wet brakes I noticed some brake fade, so I installed a 12" 8 blade fan on top of my hood vent area. It sucks the hot air out. I noticed an immediate improvement. The Vanguard ran smoother, and was running like it should. Also the KT35 wet brakes were doing what they should without fade. So now I have a real "push-pull" system. My dual fans located down low (ankle level) pull the cooler/denser air in, and the 12" exhausts it up and out. The hot air exhaust may be a bother when it gets really hot, but for now its fine. I located the 12"er, as far up the hood as possible so steep water entry won't be a problem. It will be above the 45 degree water entry line.

On my last ride I was going through this thick bush, full of hanging vines, branches etc when the Bushwacker came to a sudden and complete stop. The engine was still running so when I cleared some of the branches out of the way I noticed a large hanging vine had looped over the front bumper. In my aggressive manner I said to myself this vine is not going to stop me so I hit the throttle, but no deal. Then I started to realize that this vine was loaded up like a catapult and if it slipped up it could de-capitate me! I immediately backup and released the vine. The vine won! |

christopher j Davison

Member

Username: Chris_davison

Post Number: 24

Registered: 06-2006

Posted From: 66.81.41.36

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, May 06, 2007 - 08:05 pm: |

|

TH3

You could control this set up just like most boats control thier out board a single push pull morse cable or dual cables and pullys to the front. when you pull your lever to go right it pulls the cable to your outboard. Timming belts dont slip thier cogged to match thier pullys.

when sizing a motor remember most DC motors go 1800 rpm and one hp is 756 watts divide that by the volts and you have your amp draw from battery. now you know why trolling motors are so small. Any body thought of just hooking up a generator to thier rig say a 2500 watt 120vac to be able to run a 2hp ac motor. Then you have its use in camp also. |

christopher j Davison

Member

Username: Chris_davison

Post Number: 25

Registered: 06-2006

Posted From: 66.81.41.36

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, May 06, 2007 - 09:23 pm: |

|

Ray

It rained up here in northern Calif. yesterday and today its 88 deg. now i think its going to warm up. I was driving my 4x4 up in the sierras two weeks ago and we came to a beautiful valley covered in mist and snow made a turn and came to the dam on caples lake the valley was the frozen snowed on lake. took some pics it was beautiful. looking forward to my first fishing trip to loon lake and a backpacking trip to desolation wilderness. Were going to the alabama hills outside Lonepine ca. to view the area where they filmed the Lone Ranger and Hopalong Cassidy and many other old westerns. |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 66

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, May 17, 2007 - 07:36 pm: |

|

Hello Again, well it time for an update. The Bushwacker has turned out to be quite a machine. (if I do say so myself) I try to get about an 1/2 to an hour a day on it, and am amazed where an AATV will go. I feel pretty confident now, so I keep raising the bar. I installed a backrest (off of my Goldwing)at the rear of the straddle seat, it sure makes a difference climbing those steep hills.

Today my riding buddy (Hoot) and myself ventured into this alder swamp with a loon crap bottom. I just couldn't believe I could go through that stuff. I was leading and was picking a line that would avoid the large diameter stuff. After about 5 minutes in, I looked back and no one was following, my bud got hung up on one of those big tuffs of swamp grass. I don't know what you call them but they are like tiny islands of green grass that grow about 2-3 feet deep, you can't move them. So I turned around trying not to go over where I aleady went because all the alders are now facing you like a spears, when all of a sudden I couldn't move forward or back. I couldn't figure out why I couldn't move, I tried rocking etc. but no deal. Then I walked over the hood and looked at the front when I saw why I was stuck. A stump about 3" dia. x 3 feet long had somehow jammed itself between the bumper and the hull. I found a chunk of wood and used it as a lever to pry it out. After working it a bit, I got it out and I was free. I reversed out and picked another line and made it over to the Hoot. But wasn't watching where I was going and went into my same ruts and was stuck. Wheels were just spinning in the loon crap, so took off the shoes and socks rolled up the jeans walked through the swamp and helped get the Hoot going. Then he helped me and we both headed for dry land. What a workout, who needs exercise machines just go AATVing! |

Howard Hoover

Intermediate Member

Username: Howard_hoover

Post Number: 87

Registered: 10-2005

Posted From: 4.161.108.1

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, May 17, 2007 - 07:58 pm: |

|

Ray, I enjoyed reading your updates on the machine

hope all goes well. I'm working 60 plus hours a week and don't have time for my machine right now so nothing new here. |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 67

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, May 18, 2007 - 09:42 am: |

|

Hey Howard, too bad you're working so much, and don't have time to work on your machine. Maybe I should visit you and finish it for you, just kidding. I found as much satisfaction building as riding. Howard do you know anyone who has completed an AATV using VW or Subaru power? I would like to see some pics. for you, just kidding. I found as much satisfaction building as riding. Howard do you know anyone who has completed an AATV using VW or Subaru power? I would like to see some pics.

Another update on the Bushwacker is the use of the diff lock, I never use it. Because I found if you can't go without it, you usually can't go with it. The trick I found is to try and go straight and don't brake one side, usually there is enough traction with 6 wheels turning to keep you moving. If you can't move your usually hung up, with the 6 wheels spinning. Braking one side usually doesn't do much either I've found. Now if you don't have agressive tires, maybe its another matter, however those Mudlites may not be very good in the water, but on land their unstoppable! My top 3 priorities for an AATV would be:

1. Tires

2. Experience

3. Machine (ground clearance being the most important element)

Howard, this is how I feel now it may change down the road. Hope you find time to build again. |

Howard Hoover

Intermediate Member

Username: Howard_hoover

Post Number: 88

Registered: 10-2005

Posted From: 4.161.21.105

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, May 21, 2007 - 06:46 am: |

|

Ray, did you ever ask Chris Davison (VW) for some of his pics? although I don't think he has finished his yet. Also Pete Lanc has finished one possibly several by now with Subaru engines I have lots of his Pics but he has asked me not to forward them on to anyone like I told you before he is building them in hopes for a Military contract I think I sent you his email once before. I can get it to you again if you want to email him and ask him for some he might send you some???. |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 68

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, May 21, 2007 - 08:12 am: |

|

Howard, yes I did see some of Chris' pics, but he hasn't completed it yet. I never did see Pete's. I guess I just have to wait, until you finish yours. Was wondering how they performed? |

philip w.cox

Advanced Member

Username: Philipatmaxfour

Post Number: 336

Registered: 01-2005

Posted From: 199.246.2.9

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, May 21, 2007 - 10:46 pm: |

|

I am not a very good example of being an early bird because I have not signed up for the Ledges Ohio Ride yet myself, but I did e-mail LEO'S All Season Vehicles and have received the registration package in the mail. I note that the Deadline for registration is June 30 2007. I plan to register soon. I am trying to get a commitment from my wife but she is undecided. Ray Kohls , are you planning to attend?-----Thats what I would call testing!---You would see many different machines with many different tire combinations and people would go crazy to see your machine! |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 69

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, May 22, 2007 - 04:51 pm: |

|

Hi Philip, yes I plan on attending both Copper Ridge Olean NY, and Ledges Garretsville OH. I guess I will need to email Leo's as well to get the package. Do you know if camping is allowed on site? Also do know where I get the info regarding Copper Ridge? |

philip w.cox

Advanced Member

Username: Philipatmaxfour

Post Number: 337

Registered: 01-2005

Posted From: 64.201.47.72

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, May 22, 2007 - 11:04 pm: |

|

Ray, Very happy to hear that you plan to attend these events. Yes, camping is allowed at both events, some hydro hook-ups,some water hook-ups etc. For info. go to LINKS on this site and scroll down,click on Copper ridge or ledges. or

Copper ridge=gthropp@msn.com or phone Devin at 716-397-1584

Ledges=leosargo.com-or 440-285-1730 |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 70

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, May 23, 2007 - 08:39 am: |

|

Thanks Philip, I sent off the emails, looking forward to meeting you and the gang. |

philip w.cox

Advanced Member

Username: Philipatmaxfour

Post Number: 338

Registered: 01-2005

Posted From: 64.201.47.72

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, May 23, 2007 - 10:07 am: |

|

OOPS-I said go to "links" Wrong!-i meant, go to EVENTS. I may be losing it! |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 71

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, May 23, 2007 - 07:40 pm: |

|

Its OK Philip, I knew what you meant. Did you ever go to Copper Ridge, it seems a little mellow, or is it just me. |

philip w.cox

Advanced Member

Username: Philipatmaxfour

Post Number: 339

Registered: 01-2005

Posted From: 64.201.47.72

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, May 23, 2007 - 09:36 pm: |

|

Yes I have been there the last 3 years. I don.t know what you mean by "mellow" my friend but there are Big hills there. If you aren't impressed by this ride I'll eat at least a bite out of my cowboy hat. When the weekend is over I doubt that you will say mellow. Best wishes |

Tom Arch

Junior Member

Username: Tomarch

Post Number: 15

Registered: 07-2006

Posted From: 72.75.194.67

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, May 24, 2007 - 07:17 am: |

|

Ray, last year was my first at copper ridge and let me tell you its anything but mellow. When going down hills so steep that my max iv was on just the front tires. |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 72

Registered: 02-2007

Posted From: 74.110.30.116

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, May 24, 2007 - 04:44 pm: |

|

Ha,ha, ha, thanks Philip/Tom I will take your word for it, I guess I got the wrong impression from Gregg Thropp's email regarding Copper Ridge: "It is essentially a ride at your own pace trail ride, you roll dice to get a score for a trophy of prize 1st 2nd 3rd and last. Food is available , The trails are good." From your description it seems anything but mellow, your cowboy hat is safe Philip. |

Howard Hoover

Intermediate Member

Username: Howard_hoover

Post Number: 93

Registered: 10-2005

Posted From: 4.161.104.89

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, June 27, 2007 - 07:18 am: |

|

Ray, How is your machine doing? any more problems

with it or did you get all the bugs worked out. |

philip w.cox

Advanced Member

Username: Philipatmaxfour

Post Number: 358

Registered: 01-2005

Posted From: 199.246.2.9

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, June 29, 2007 - 10:33 pm: |

|

Ray-Olean N.Y. (Copper Ridge) event is only 17 days away. Are you still intending to be there? I am about to do some comparison tire tests in the water. Would like to compare notes with you. W. Philip Cox |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 74

Registered: 02-2007

Rating:

Votes: 1 (Vote!) | | Posted on Saturday, September 08, 2007 - 09:59 am: |

|

Hello everyone, thanks for all you comments over the past months. I did finish all my testing and enjoyed the sport tremendously! I'm probably hooked for life. The Bushwacker turned out to be a fine machine (if I do say so myself), admired by Argo owners (no Maxes in my area)and other ATV guys, it really could go anywhere, made me nervous at times...can I really go through there!! and now how am I going to get out!! But it never let me down.

The only real design change I made was to add an additional cooling fan on top of the hood exhausting the heat from the engine/tranny area. So that made a total of 4 yes 4 exhaust fans. Two lower fans to bring cool air into the engine, One for the muffler to cool the hood contact area, and one large one on the hood to exhaust the heat.

I found that excessive heat really affects performance of the drive train. The 23 hp. Vanguard will run rich, and lose power, and the wet brakes in the Tuff Torq KT-35 will fade, and be harder to turn. Another observation, is tire selection, those Mudlite 25x12x9 tires are an excellent tire in all conditions except water. There are light, 6 ply, and give an excellent soft ride at 2-3 psi., however not being a skid steer tire they are very hard to turn (skid).

I am sorry that I didnt have time to get to one of your events so far, but will make it there eventually. I bought a Honda Goldwing 1800 and a camper trailer and did about 7,000 miles in Canada and the USA. this summer, but did miss AATVing.

Now the sad news I sold my Bushwacker to a fellow in NE Manitoba, who is a tourist outfitter, who intends to put the Bushwackers fine qualities to work, hauling stuff, and tourists etc. What a dream area for AATVing. Miles after mile of lakes, rivers and trails, bear, moose, deer, grouse, ducks......WOW. So what do I do now!

I'm thinking about a new design that I will discuss on another post, as well as taking an Attex and redesigning it to suit myself. You guys will be hearing from me soon, I'm addicted! |

Dave Evans

Member

Username: Dozer

Post Number: 37

Registered: 01-2001

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, September 08, 2007 - 09:05 pm: |

|

Ray I have really enjoyed your project, please keep us posted on the new one, take lots of photos, What trans are you going to use this time? Dave |

Ryan Singer

New member

Username: 6x6mudder

Post Number: 9

Registered: 07-2007

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, September 08, 2007 - 10:17 pm: |

|

Ray, sorry I missed your machine, you mean you built a machine yourself from your own design, got any photos for us newbes Thanks 6X6MUDDER RYAN SINGER |

Ryan Singer

Junior Member

Username: 6x6mudder

Post Number: 10

Registered: 07-2007

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, September 10, 2007 - 10:19 am: |

|

Ray, I would love to see some construction photos?

Thanks 6X6MUDDER RYAN SINGER |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 75

Registered: 02-2007

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, September 10, 2007 - 02:12 pm: |

|

Hello again, I will be posting the whole development story along with construction pics of the design/build process. Richard was kind enough to offer a spot on "Reader Rides" on his website to showcase this project. Please follow the Bushwackers' progress from a scale model to completion. The 1st installment has been sent, it should be posted shortly. |

Dave Evans

Member

Username: Dozer

Post Number: 38

Registered: 01-2001

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, September 10, 2007 - 05:03 pm: |

|

Ray i am looking forward to seeing the photos all in one spot Dave |

Dave Evans

Member

Username: Dozer

Post Number: 41

Registered: 01-2001

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, September 12, 2007 - 09:46 pm: |

|

Ray, just got notice from the route66 subscription, that your articles were posted on the readers section, sure looks nice, I really like your model plans, wish i could do it. Give us some hints of your new design, ever thought of building a machine to sell? |

Bryan Jaedike

Junior Member

Username: Tigerguy

Post Number: 18

Registered: 02-2007

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, September 13, 2007 - 06:44 pm: |

|

What a machine, looking great, lets see more Bryan |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 76

Registered: 02-2007

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, September 13, 2007 - 07:20 pm: |

|

Thanks for all your comments, It is not all that hard to design/build your own machine. If you don't have the skills you can farm out whatever area you lack in. Get quotes and proceed accordingly.

I have thought about building a machine and taking it to market, if there was enough interest and investors I may consider it. Another approach would be to sell plans so others could build a Bushwacker.

My new design is indeed revolutionary. The concepts are far reaching, it will be a true 4 season machine. High water speed, deep snow won't be a problem, right now I can't see any type of terrain stopping it. Thats all I can say right now. Stay tuned, you won't believe your eyes! This will be the machine that Argo/Max and Bombardier should have built. |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 77

Registered: 02-2007

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, September 18, 2007 - 08:43 am: |

|

Got lonesome without my Bushwacker so I bought a Max 11 16hp, with top. I have a couple of projects for this machine one is dual axle seals retrofit kit, dual prop drive and 24" Frontier tires. When completed I will post pics and vids (if successful). My design goal is 10 mph, which is around max. hull speed, which will make it a challenge. When completed I will sell the Max 11, buy a Argo Bigfoot and do the same, minus the axle seals.

Another reason for buying the Max was to check out the famous T-20, read alot about it but never tried one or even seen one in action, lets see if it deserves its excellent rep. Also it will serve as a test bed for my forthcoming new AATV.

You know sometimes I feel guilty, I'm having way too much fun!!  |

Dave Evans

Member

Username: Dozer

Post Number: 49

Registered: 01-2001

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, September 20, 2007 - 10:25 am: |

|

Ray, it will be interesting to see that you think of this older max and argo's Machine looks pretty nice, is it? Dave |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 78

Registered: 02-2007

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, September 20, 2007 - 05:20 pm: |

|

Well Dave, had my first ride and look at my Max II.

The Good: Nice size, layout, seating, legroom, ride ok, drive train is enclosed so not too much dirt, debris can get in, roll bar, and very tight turns. Primary drive looks ok, motor, driver/driven ok, T-20 looks ok.

The Bad: Looks like the T-20 is going to take some time to get used to. It seems like it has a very narrow sweet spot, if you over/under shoot it gets jerky. It easy to do tight turns harder to do slightly larger smooth turns. Shifting into forward/reverse takes some finese, pulling sticks back, rocking etc, not too smooth, makes alarming noises but may be just the nature of the beast. I don't think it will be too forgiving, I don't think its something you adjust and forget.

I think inverted "L" shaped laterals will give better control, especially for newbies. Giving it throttle and pulling back on the stick, takes some getting used to. A thumb throttle on an inverted "L" lateral would be much better in my mind.

Getting at the drive train for inspection/maintenance is a pain. They could have simplified it by having quick release fasteners (zeus) or such on the body. Also the roll bar, why not a simple quick release pin? Same for the seat belt fasteners, and seat. The pivoting bar for holding up the body is great!

The Ugly:

The secondary drive sucks, #40 chain, chain tensioners on the top, hollow axles/sleeves, thin 3 bolt flanges, shear bolts, thin metal frame, no skid plates, poor designed drain holes/plugs, no cargo room.

Now to be fair I'm sure this is not representative of Max's new stuff, I don't know the vintage, was told its a 1998, but can't believe it. If it is a 1998 then shame on Max. If it is representative of their products then I want to be in the Max part business! Having said all that, I think it has potential, and will make an excellent ride, after I update it.} |

Dave Evans

Intermediate Member

Username: Dozer

Post Number: 52

Registered: 01-2001

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, September 20, 2007 - 06:25 pm: |

|

Well Ray , looks like you have bought some old junk, sorry to say. You should go easy on MAX since your unit is so dated.

#40 chain went out in the 1970's so that dates machine to be 30 years old, OUCH. Shear bolts left in the 1990's too, biger bearings and flanges. Same crapy chain adjusters, I guess that is why Richard has new ones for sale. Frame is stronger on newer machines too.

Also a t20 is a great unit, sounds like yours is as old as your machine and needs repair too..

Hate to say but it looks like you bought some sad 1970's machine which needs work, but with a newer engine. Also notice wrong tires with make everything worse. Sorry, I am sure others will point out differences too. I thought the roll bar did have a quick disconnect?

with your talent you can improve that old max in many ways, keep us posted.. Dave |

Ray Kohls

Intermediate Member

Username: Bw6

Post Number: 79

Registered: 02-2007

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, September 20, 2007 - 07:20 pm: |

|

Dave, thanks for the feedback, glad to hear that Max has made the necessary updates over the years. Well all is not lost. It may be junk now but over the next little while I feel I can transform it into a decent machine. The engine, driver/driven all look fairly new, so does the T-20. I will be evaluating it and seeking advice soon. There are many things I like about this machine, I think it has potential. I didnt pay all that much for it, so I don't feel too bad. The tires have got to go, they are new, but never heard of Lumber Jack brand and don't like the tread pattern. I never noticed any kind of serial number or factory info, so how does one really determine the year? |

Dave Evans

Intermediate Member

Username: Dozer

Post Number: 53

Registered: 01-2001

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, September 20, 2007 - 08:19 pm: |

|

Ray Maybe I was being to nice to the MAX, they do use the crappy jackshafts, why just adds lots of moving parts, and the chain adjusters, richard makes good ones, why can't the factory? Rider comfort is nice with lots of legroom.

You can date machine pretty well by the #40 sprockets which were droped in late the 1970's,, which means your machine was made in the 1970's

Dealers on this board most likely give a better date range.

Most people use and like the Rawhide tire best or use the chevron for a better ride and handling

I bet you have a great time with it Dave |

Eddie Chace

Junior Member

Username: Wildtexasranger

Post Number: 13

Registered: 11-2006

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, September 20, 2007 - 11:34 pm: |

|

Dave there should be a number stamped on the right side of the frame on top just right under the seat.I just wanted you to check out maxxis mud bug tires.I know they swim just as good as rawhides but really grab the mud like gators just thought id pass that tid- bit on!!!!

I have a 72 max 2 that Im building up and cant wait to see what you do to yours.I know you will like what it can do;If I can help you out just send me an e-mail |

Eddie Chace

Junior Member

Username: Wildtexasranger

Post Number: 14

Registered: 11-2006

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, September 20, 2007 - 11:44 pm: |

|